Vulgarisation des connaissances sur les guides linéaires

Nov 21, 2025

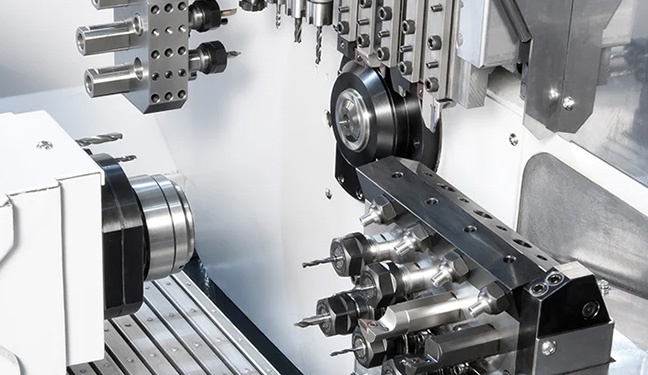

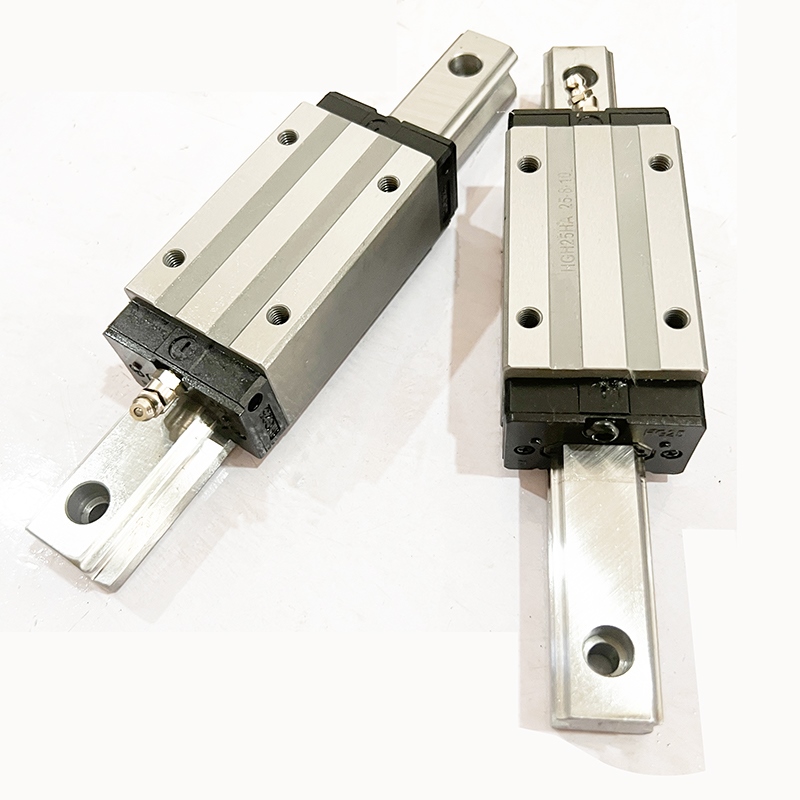

【guides linéaires】Les guides linéaires peuvent être classés en trois catégories : guides à billes, guides à rouleaux et guides à roues. Ils servent à supporter et guider les pièces mobiles, leur permettant d’effectuer un mouvement linéaire alternatif dans une direction donnée. Selon la nature du frottement, on distingue les guides à frottement de glissement, les guides à frottement de roulement, les guides à frottement élastique et les guides à frottement fluide. 1. Définition : Les guides linéaires, également appelés rails linéaires, rails de glissement ou guides linéaires, sont utilisés dans les applications de mouvement linéaire alternatif et peuvent supporter une certaine quantité de couple, permettant un mouvement linéaire de haute précision sous des charges élevées. 2. Fonction : Les guidages linéaires servent à supporter et guider les pièces mobiles, leur permettant d'effectuer un mouvement linéaire alternatif dans une direction donnée. Ils sont principalement utilisés dans les machines automatisées, telles que les machines-outils importées d'Allemagne, les presses plieuses et les machines de soudage laser. Les guidages linéaires sont généralement utilisés conjointement avec les arbres linéaires. Ils sont principalement utilisés dans les structures mécaniques exigeant une grande précision. Les éléments mobiles et fixes d'un guidage linéaire ne nécessitent pas de milieu intermédiaire ; des billes d'acier sont utilisées à la place. 3. Principe de fonctionnement : Ce système peut être comparé à un guide à roulement, où des billes d'acier roulent et circulent en continu entre le curseur et le rail de guidage, permettant ainsi à la plateforme de charge de se déplacer facilement et linéairement le long du rail avec une grande précision. Ceci réduit le coefficient de frottement à un cinquantième de celui des guides à glissement traditionnels, permettant d'atteindre facilement une très grande précision de positionnement. La conception de l'unité d'extrémité entre le curseur et le rail de guidage permet à ce dernier de supporter simultanément des charges dans toutes les directions (haut, bas, gauche et droite). Le système de recirculation breveté et la conception structurelle simplifiée rendent ce système particulièrement performant. Rails de guidage linéaires HIWIN Le mouvement est plus fluide et plus silencieux. Le curseur transforme le mouvement courbe en mouvement rectiligne. À l'instar des rails de guidage plans, les rails de guidage linéaires comportent deux éléments principaux : un élément fixe servant de guide et un élément mobile. Les rails de guidage linéaires étant des composants standard, les fabricants de machines-outils n'ont qu'à usiner un plan de montage et ajuster le parallélisme du rail. Ce dernier, en acier trempé, est rectifié avec précision avant d'être installé sur le plan de montage. Par exemple, un système de rail de guidage conçu pour résister à la fois aux forces linéaires et aux moments de renversement diffère sensiblement d'un rail conçu uniquement pour les forces linéaires. Avec le temps, les billes d'acier s'usent, réduisant la précharge et la précision de mouvement des pièces mobiles de la machine-outil. Pour maintenir la précision initiale, il est nécessaire de remplacer le support du rail de guidage, voire le rail lui-même. Si le système de rail de guidage est déjà préchargé et que sa précision est altérée, la seule solution consiste à remplacer les éléments roulants. Le système de rail de guidage est conçu pour maximiser la surface de contact entre les éléments fixe et mobile. Cela améliore non seulement la capacité de charge du système, mais lui permet également de résister aux forces d'impact générées par une coupe intermittente ou intensive, en répartissant largement la force et en augmentant la surface portante. Pour ce faire, les systèmes de rails de guidage utilisent différentes formes de rainures, dont deux types représentatifs : les rainures gothiques (en arc brisé), qui prolongent un demi-cercle dont le point de contact se situe à la pointe ; et les rainures en forme d'arc, qui remplissent la même fonction. Quelle que soit la forme structurelle, l'objectif est le même : maximiser le rayon de contact des billes d'acier avec le rail de guidage (élément fixe). Le facteur déterminant des performances du système est la manière dont les éléments roulants entrent en contact avec le rail de guidage. 4. Domaines d'application : ① Les guides linéaires sont principalement utilisés dans les machines automatisées, telles que les machines-outils importées d'Allemagne, les machines de pliage, les machines de soudage laser, etc. guides linéaires et arbres linéaires sont utilisés conjointement. ② Les guides linéaires sont principalement utilisés dans les structures mécaniques exigeant une grande précision. Les composants mobiles et fixes d'un guide linéaire ne comportent pas d'intermédiaire, mais des billes d'acier. En effet, ces billes sont adaptées aux mouvements à grande vitesse, présentent un faible coefficient de frottement et une grande sensibilité, répondant ainsi aux exigences de fonctionnement des pièces mobiles, telles que les porte-outils et les glissières de machines-outils. Si la force appliquée sur les billes d'acier est trop importante, ou si le temps de précharge est trop long, la résistance au mouvement du support augmentera. 5. Précautions d'emploi : Prévention de la corrosion : Lors de la manipulation directe des guides linéaires, lavez-vous soigneusement les mains pour éliminer toute trace de transpiration et appliquez une huile minérale de haute qualité avant toute manipulation. Portez une attention particulière à la prévention de la corrosion pendant la saison des pluies et en été. Maintien d'un environnement propre : Veillez à ce que les guides linéaires et leur environnement restent propres. Même de fines particules de poussière invisibles à l'œil nu qui pénètrent dans les guides augmentent l'usure, les vibrations et le bruit. L'installation requiert une attention particulière. Les guides linéaires doivent être installés avec le plus grand soin. Les chocs violents, les coups de marteau directs et la transmission de pression par roulement sont strictement interdits. L'utilisation d'outils d'installation appropriés est essentielle. Utilisez des outils spécialisés chaque fois que cela est possible et évitez l'utilisation de chiffons ou de matériaux à fibres courtes. 6. Nettoyage des guides : Composants essentiels de l'équipement, les guides et les arbres linéaires servent à la fois de support et de guide. Pour garantir une précision d'usinage élevée, les guides et les arbres linéaires doivent présenter une grande précision de guidage et une bonne stabilité de mouvement. Pendant le fonctionnement, la pièce génère d'importantes quantités de poussières et de fumées corrosives. L'accumulation à long terme de ces poussières et fumées sur les surfaces des guides et des arbres linéaires a un impact significatif sur la précision d'usinage et peut provoquer des piqûres, réduisant ainsi la durée de vie de l'équipement. Pour assurer un fonctionnement stable de la machine et la qualité des produits, un entretien régulier des guides et des arbres linéaires est crucial. Remarque : Pour nettoyer les guides, munissez-vous d'un chiffon en coton sec et d'huile lubrifiante. Les guides des machines de gravure se divisent en guides linéaires et guides à rouleaux. Nettoyage du rail de guidage linéaire : Commencez par déplacer la tête laser complètement à droite (ou à gauche) pour localiser le rail de guidage linéaire. Essuyez-le avec un chiffon en coton sec jusqu'à ce qu'il soit brillant et exempt de poussière. Appliquez une petite quantité de lubrifiant (l'huile pour machine à coudre convient ; n'utilisez pas d'huile moteur). Déplacez lentement la tête laser de gauche à droite à plusieurs reprises pour répartir uniformément le lubrifiant. Nettoyage du rail de guidage du rouleau : Déplacez la traverse vers l’intérieur, ouvrez les capots d’extrémité des deux côtés de la machine, repérez le rail de guidage et essuyez les zones de contact entre le rail et le rouleau avec un chiffon en coton sec. Replacez ensuite la traverse et nettoyez les zones restantes. 7. Perspectives de développement : Avec l’expansion continue de secteurs tels que l’énergie, les télécommunications, les transports ferroviaires urbains, l’automobile et la construction navale, la demande en rails de guidage linéaire va croître rapidement. L’industrie des rails de guidage linéaire présente un fort potentiel de développement. 【Bloc coulissant】Le matériau du bloc de glissement présente une dureté et une résistance à l'usure appropriées, suffisantes pour supporter le frottement lié au mouvement. La dureté de la partie cavité ou noyau du bloc de glissement doit être identique à celle des autres parties de la cavité et du noyau du moule.1. Équipements de procédés industriels : Les moules sont des équipements essentiels à la fabrication de divers produits industriels. Avec le développement rapide de l’industrie des plastiques et l’utilisation généralisée des produits plastiques dans les secteurs de l’aérospatiale, de l’électronique, de la mécanique, de la construction navale et de l’automobile, les exigences relatives aux moules sont de plus en plus strictes. Les méthodes de conception traditionnelles ne suffisent plus. Comparée à ces méthodes, la conception assistée par ordinateur (CAO) offre des avantages considérables en termes d’amélioration de la productivité, de garantie de la qualité des produits, de réduction des coûts et d’allègement de la pénibilité du travail. 2. Applications : Largement utilisé dans les équipements de pulvérisation, les machines-outils CNC, les centres d'usinage, l'électronique, les machines automatisées, les machines textiles, l'automobile, les dispositifs médicaux, les machines d'impression, les machines d'emballage, les machines à bois, la fabrication de moules et bien d'autres domaines. Si vous avez des questions à ce sujet, nos experts produits se feront un plaisir d'y répondre ! Notre équipe d'ingénieurs répondra avec plaisir à vos questions techniques concernant les applications de nos produits dans les meilleurs délais. Cet article a été compilé à partir de sources en ligne dans le but de diffuser davantage d'informations. S'il porte atteinte à vos droits, veuillez nous contacter pour le supprimer. Pour toute information concernant les vis-mères, les rails de guidage, les coulisseaux, les broches et les machines-outils, n'hésitez pas à nous contacter.

RÉSEAU PRIS EN CHARGE

RÉSEAU PRIS EN CHARGE